(This is the building article, for the completed model, please go here:

http://wingsofintent.blogspot.com/2017/07/modified-vacuum-formed-joystick-models.html

http://wingsofintent.blogspot.com/2017/07/modified-vacuum-formed-joystick-models.html

Post-WW1 conversions for carrying passengers mostly consisted of putting on a sort of "hat" in the guise of enclosed

cabin, conferring to the lines of the plane a strange, if ultimately lovable

look.

Long ago I made this "limousine":

(scroll down quite a bit once there:)

And then these ones:

The Rumpler C.I (or 5A2) was converted to a limousine by

that same procedure. It was used by a short-lived German passenger airline know

as Rumpler-Luftverkehr, or "that airline" for us not ready to venture

in the pronunciation of German.

My dear friend from Marzipanland, a province of Volkania,

Sönke Schulz, and your humble have been interested in this machine for some

time. Beware that at some point in the 30s a spurious hybrid (also named D290)

was concocted for Lufthansa propaganda purposes and exhibited at a German

museum, easy to tell apart from the original for many details, the most obvious

perhaps a strange vertical stabilizer that has nothing to do with the Rumpler

C.I, and wings that belonged to a C.IV.

Painful and slow research provided now with data enough to

build a model of the original.

Many of you know my love for vacuum-formed kits. I got a

quite nice Joystick Models (England)

Rumpler C.I from Jeff and Liz in the Palm

Desert area. You can see

the kit in the photos below.

The kit is interesting, and as vacs go quite good. There are a couple things, though: the plan included in the instructions doesn't match the kit parts (or vice-versa), sometimes for more than a 1/4 inch. Those instructions do not have an exploded view or any indication as to where things go, but it's easy enough to guess. Some detail:

A bit wonky metal parts:

Nice scale drawing, some historical notes and some modeling advise:

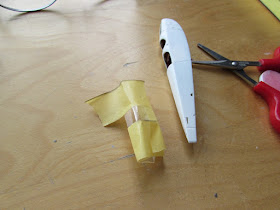

You may like to replace the vac engine molded into the fuselage. In this case an Engine & Things item. I carved a laminated prop, but also pulled a plastic spare from the bin (thanks Jim). Now inoperative Aeroclub provided long ago the needed exhaust (thanks Armando). Metal Strutz (thanks Andrew!) will replace the kit's too flimsy ones:

Fifteen minutes later, all the relevant parts are extracted from the main sheet, although as we know some sanding will be involved to true the joining parts and thin the flying surfaces.

You may notice that there is no provided undersurface for wings and stab, due to the original thinness of those surfaces in the original plane. You must concoct some way to represent ribs underneath, may be some faded colored pencil, engraving, application of strips, etc.

As you can see some interior is provided:

The trailing edges are thinned with some exercising sanding:

The fuselage sides match very well:

Engine removed, the beginnings of the cutouts:

Thingy to be removed:

A pleasant and soothing view of the components

The radiator (that goes on the upper wing leading edge) needs to be given the other side:

So it is glued on a thin piece of scrap, later to be cut and contoured:

I made a new vertical stabilizer, since the kit's is "one-sided" and more difficult to fix than to make a new one:

A side view is printed to generate a pattern:Later transferred to a wood block of correct thickness:

The block is given preliminary shape. It will eventually be used to produce a vacuum-formed part:

The fuel tank was relocated outside to create room for the cabin, on the fuselage aside the pilot, in the form of a sort of airfoiled saddle that looked more like the buttoned pillow of a sofa:

The wood master is used to create the canopy:

Little by little the vac part is trimmed:The front and aft edges rounded to match the fuselage curves:

The luxurious interior is fabricated:

Even if I am most likely not use the kit's prop, I felt compelled to fix it (it was a casting mess as you can see at the beginning of the post). Also the stem of the kit's prop was off-set, so it had to be trimmed off:

The general situatiuon:Landing gear in progress:

The intrados of the flying surfaces is engraved using the double-whammy Olfa P maneuver to create the effect of rib tapes.

The fuselage is given some tabs to secure alignment and a firmer bond with more area once the halves are joined:

Parts are washed and let dry:

. Scrutinize the parts to be sure you did not lose any:

The general colors of the interior are airbrushed. Later on other colors will be applied:

Some more painting and details follow:

The interior is ready:

The fuselage halves are joined:

The extreme thinness of the wings poses some issues: they can't be drilled to install a locating pin, or drilled deep enough to secure a strut. The strut locations on the upper wing where slightly marked, whilst the kit already had some dimples on the lower wings.

To secure the latter to the fuselage sides, tabs were added:

Same for the stab:Another group view:

All the basic elements are now present, but still some serious work lies ahead:

The absence of aileron control horns in the reference photos lead me to find the unusual mechanism that actuated the surfaces. Here is a sketch I made:

The tail surfaces are given their control horns and prepared

The locating devices worked fine:

Here are the slots for the stabs:

The fuselage's seams filling in progress:

Dry-fit of the canopy

Preparing to cut the door:

Door separated:

The landing gear in place:

The same device used to secure the stabs is used for the lower wings, tongue and slot:

Before gluing make sure all aligns and get the correct dihedral (dry-run here):

The canopy, once bathed in floor polish, is let to dry, and then isolated in a separate container until needed:

The kit's strut material was quite insufficient, so I had to get some from my stock. Struts are measure and cut, the upper wing is bent to it's dihedral (the kit molds it as flat, for practical purposes):

The lower wing halves are glued, and let to dry also propped with their correct dihedral and alignment:

The cabane is fabricated:

Tail feathers in place:Primer is applied:

Canopy is on and masked, and color airbrushed:

The saddle fuel tanks are given their straps as decals:

The radiator and exhaust are painted:

Masks are removed, engine installed. All components ready. The more delicate task of strutting and rigging is ahead, plus the cables for the control surfaces and eventually decaling:

The radiator is glued to the upper wing. The pilot's windshield is added. Saddle fuel tanks are also glued in place, as well as struts:

The cabane is assembled in its correct angle on the side:

The cabane is glued in position.The "no step" area on the lower left wing is given a red decal, cut from stock. The door is provided with its upholstery the same way (a decal). Fuel lines connect now external tanks and fuselage:

A superglue spillage required some remediation. Drat and flying snakes:

Radiator plumbing, exhaust manifold, wheels and prop in place. In the back can be seem the small struts for the stabilizer, ready to be cut to size and glued:

All rigging in place now:

Decals and door are the only things needed now:

I used the kit's prop, since I could not find a photo of a plane with a laminated one, so my home-made wood creation will have to go to the spares bin for a future project::

The wonderful decal set from Arctic Decals:

No comments:

Post a Comment