For the completed model see here in this blog:)

http://wingsofintent.blogspot.com/2014/12/panagra-fairchild-fc-2w2-completed.html

Let's see: I am building as said the Kalinin AK-1, the K-5 and the S.79 the Corsa, all those posts are open in this blog, what could be better than to start yet another project?

And since I just posted the Bellanca CH-300s Tiolene and

Inter Island Airways, let's follow with another Khee-Kha product: the Fairchild

71, converted in this case to a Fairchild FC-2W flown by PANAGRA (Pan American

Grace Airways) in South America.

I have built one of these kits for my son long ago, also a conversion, that can be seen here in this blog:

http://wingsofintent.blogspot.com/2014/07/172-khee-kha-art-products-vacuformed.html

I have built one of these kits for my son long ago, also a conversion, that can be seen here in this blog:

http://wingsofintent.blogspot.com/2014/07/172-khee-kha-art-products-vacuformed.html

After much hesitation and pondering about what to do this time with

that 71 I decanted for a machine that was flown in Argentina

(amongst other destinations), basing my work on a photo found on the Net of a plane that landed in Buenos Aires. This is the link to the site and specific article:

http://www.histarmar.com.ar/AVIACION/ApeaderoPuertoNuevo/ApeaderoPuertoNuevo.htm

In that quite blurry image you can distinguish the PAA Grace logo, visibility stripes on the tail and wing, a designation P-4 and the registration NC8039. This same machine can be seen in other photos with different schemes, but this one, together with a very tempting P.A.G.A.I. incarnation with a stylized bird logo, where the ones that made it to the finals. I desisted of the PAGAI one because the colors were more uncertain than those of the one finally chosen.

The chosen subject suffered crashes and many modifications in its career, and it is seen in the main reference photo with a very special window arrangement, and seemingly as if the aft bulkhead had been perhaps moved back a little to add cabin space.

http://www.histarmar.com.ar/AVIACION/ApeaderoPuertoNuevo/ApeaderoPuertoNuevo.htm

In that quite blurry image you can distinguish the PAA Grace logo, visibility stripes on the tail and wing, a designation P-4 and the registration NC8039. This same machine can be seen in other photos with different schemes, but this one, together with a very tempting P.A.G.A.I. incarnation with a stylized bird logo, where the ones that made it to the finals. I desisted of the PAGAI one because the colors were more uncertain than those of the one finally chosen.

The chosen subject suffered crashes and many modifications in its career, and it is seen in the main reference photo with a very special window arrangement, and seemingly as if the aft bulkhead had been perhaps moved back a little to add cabin space.

As it is customary I will be posting in-progress

images of the build, but I have posted so many articles on building these vacs that

you can consult searching on this same blog for additional info if you need

any.

And so it begins:

What you get: the vacuum-formed sheet with the parts + resin bits and clear parts + instructions & references:

The provided impeccable resin bits and windshield, plus window material:

Marking with a sharpie the contours of the parts. There are parts I won't use, like spar, struts, oleos, etc. All these will be replaced:

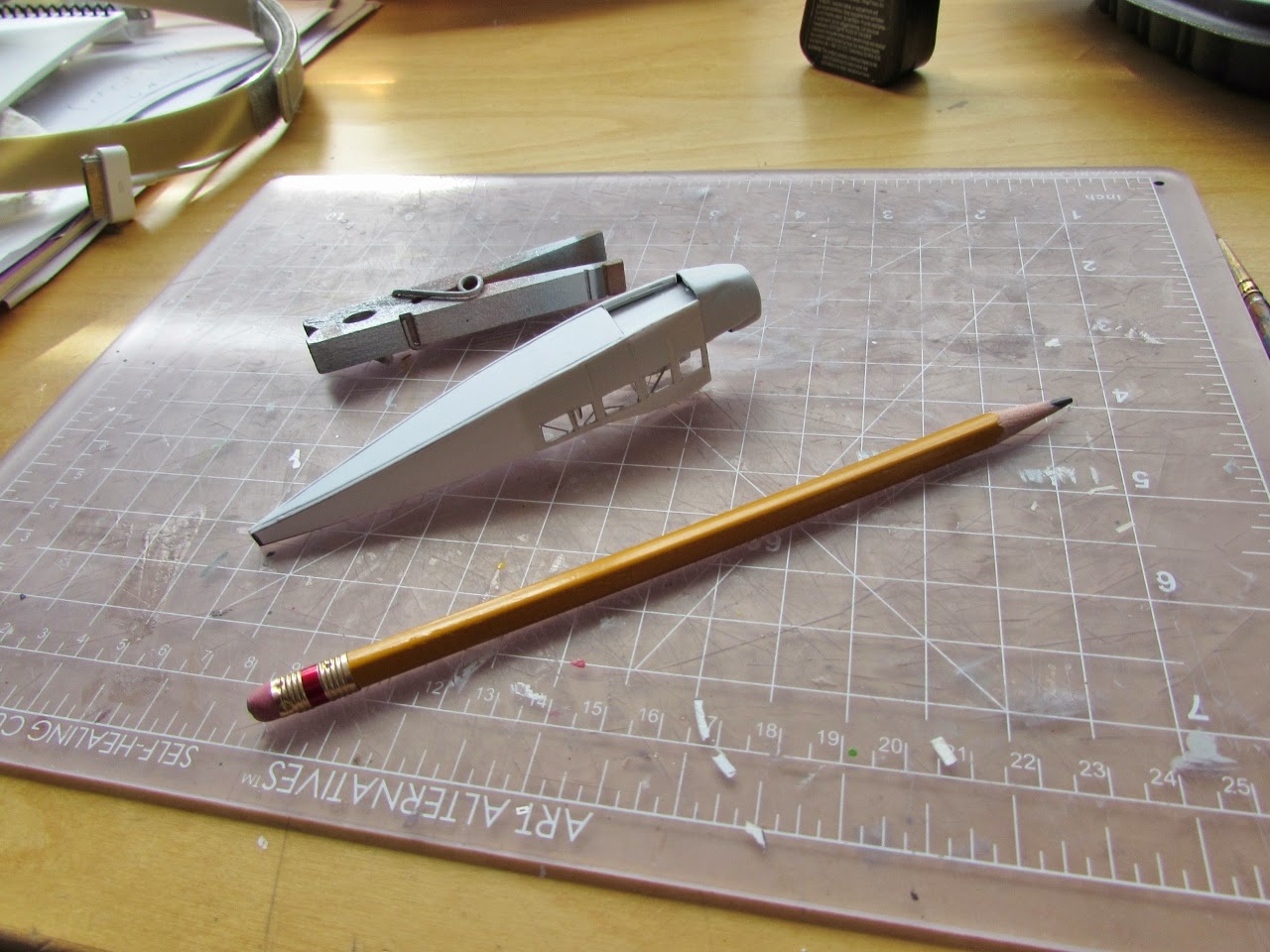

Cutting the parts:

Gluing the halves after careful sanding down, matching, trimming:

A change in the recommended building sequence: keeping the upper half of the wings attached to the center section:

Dihedral carefully bent-in and center section plus ailerons and flaps engraved with an Olfa P cutter:

Drilling the locations for the wing struts, marked on the molds by the manufacturer . The width of the gap will be adjusted once the fuselage is built:

The duplicated sections are removed from the nose parts, again taking a sui generis approach:

The window configuration (different and specific to this particular machine) is marked:

The windows are marked now with a new blade, carefully, their centers drilled:

The "petals" are gently bent back and forth until they detach:

Some refining usually follows:

The parts so far. The nose halves have been glued, the "glass" solid representation removed. One bulkhead was fashioned from the backing sheet leftovers. The front door on the left fuselage side is covered in putty to erase it, later of course it will be sanded flush. The kit's very nice seat and the inst. panel can be seen too:

The fuselage sides are given longerons to support the floor. The bulkhead is glued to the floor:

The elevators are cut out and re-glued in a more natural position:

The passenger seats are made:

The inst. panel is glued to the nose, and a support is added to the pilot's seat:

Since this plane had a tail wheel, suitable candidates are considered. The resin part is actually a Khee-Kha's product that comes with their Bellanca. Airfoiled metal struts are also set apart to replace the ones in the kit:

Each window pane is measured, cut, and trimmed to fit. They fit snuggly, so no cement is usually needed:

Once all is ready, they are popped-out with the rubber tip of a pencil, and coded so they can be re-positioned after painting of the interior surfaces. Other modelers would perhaps prefer to cut out a single continuous window pane on the fuselage side and use external masking or decal strips to simulate the framing:

The interior is painted:

The cabin floor is constructed as an independent module:

General view:

The windows are re-inserted after painting:

Some structure is added:

The aft fuselage sides and aft floor are glued together, the slide-on cabin floor on the side:

Nose prepared for a dry run:

Good fit:

The tail group is given proper details in the form of control horns and anchoring pegs:

The sleeved struts are prepared:

the sleeve is glued:

and voilá:

Another dry test of the nose, which cheeks have been given small tongues to help positive location and gluing:

Home-made decals are printed. There are two sets of registrations, the first is what I see in some Panagra photos, the second is the standard Amarillo font which was not used in this particular machine -but I had included nevertheless- in case other incarnation of the plane in the same regs may need them in the future:

The isnt. panel decal in place, further detailing of seats on the slide-in cabin floor:

A view of the involved components of this stage:

Everything is carefully glued:

Side view:

Bottom view. The gap on the floor is going to be covered with styrene sheet, and then other elements added to match the nose bottom shape:

Filling of "the gap". Further fairing will added later on::

Dry-run of the wing "seating":

Spreader/reinforcement added:

Look, mom, no spars!:

Everything seems to work:

Small locating holes are drilled where needed, for the landing gear, control cables, reinforcement struts, etc.:

The two front triangular window panes are cut and adjusted, so is the vacuformed windshield provided with the kit:

Landing gear components in place together with small skid. Tail wheel to be added later.

The resin engine "antler" exhausts fit nothing less than perfectly, chapeau to the kit maker:

Painting begins by airbrushing a base of white and black on different parts:

The other colors are applied, after some masking. I sprayed a decal paper with red, since the wing has red areas, but ended up just doing some more masking and painting the wing instead:

The front of the fuselage was done in a polished hue to resemble the real metal, whilst the rest of the fuselage was given an aluminum color to resemble alu doped surfaces:

The masked and spayed wing:

results:

Decaling:

Triangular front window panes, main wheels and tailwheel in place:

The wing is glued:

Wing struts and nav lights in place:

The window configuration (different and specific to this particular machine) is marked:

The windows are marked now with a new blade, carefully, their centers drilled:

The "petals" are gently bent back and forth until they detach:

Some refining usually follows:

The parts so far. The nose halves have been glued, the "glass" solid representation removed. One bulkhead was fashioned from the backing sheet leftovers. The front door on the left fuselage side is covered in putty to erase it, later of course it will be sanded flush. The kit's very nice seat and the inst. panel can be seen too:

The fuselage sides are given longerons to support the floor. The bulkhead is glued to the floor:

The elevators are cut out and re-glued in a more natural position:

The passenger seats are made:

The inst. panel is glued to the nose, and a support is added to the pilot's seat:

Since this plane had a tail wheel, suitable candidates are considered. The resin part is actually a Khee-Kha's product that comes with their Bellanca. Airfoiled metal struts are also set apart to replace the ones in the kit:

Each window pane is measured, cut, and trimmed to fit. They fit snuggly, so no cement is usually needed:

Once all is ready, they are popped-out with the rubber tip of a pencil, and coded so they can be re-positioned after painting of the interior surfaces. Other modelers would perhaps prefer to cut out a single continuous window pane on the fuselage side and use external masking or decal strips to simulate the framing:

The interior is painted:

The cabin floor is constructed as an independent module:

General view:

The windows are re-inserted after painting:

Some structure is added:

The aft fuselage sides and aft floor are glued together, the slide-on cabin floor on the side:

Nose prepared for a dry run:

Good fit:

The tail group is given proper details in the form of control horns and anchoring pegs:

The sleeved struts are prepared:

the sleeve is glued:

and voilá:

Another dry test of the nose, which cheeks have been given small tongues to help positive location and gluing:

Home-made decals are printed. There are two sets of registrations, the first is what I see in some Panagra photos, the second is the standard Amarillo font which was not used in this particular machine -but I had included nevertheless- in case other incarnation of the plane in the same regs may need them in the future:

The isnt. panel decal in place, further detailing of seats on the slide-in cabin floor:

A view of the involved components of this stage:

Everything is carefully glued:

Side view:

Bottom view. The gap on the floor is going to be covered with styrene sheet, and then other elements added to match the nose bottom shape:

Filling of "the gap". Further fairing will added later on::

Dry-run of the wing "seating":

Spreader/reinforcement added:

Look, mom, no spars!:

The upper cover of the fuselage in place. The window area is covered with tape and the interior plugged with damp tissue paper to allow for the puttying and sanding of the fuselage joints :

Wing trimmed and dry-fitted to get the flaps cleared:Everything seems to work:

Small locating holes are drilled where needed, for the landing gear, control cables, reinforcement struts, etc.:

The two front triangular window panes are cut and adjusted, so is the vacuformed windshield provided with the kit:

Landing gear components in place together with small skid. Tail wheel to be added later.

The resin engine "antler" exhausts fit nothing less than perfectly, chapeau to the kit maker:

Painting begins by airbrushing a base of white and black on different parts:

The other colors are applied, after some masking. I sprayed a decal paper with red, since the wing has red areas, but ended up just doing some more masking and painting the wing instead:

The front of the fuselage was done in a polished hue to resemble the real metal, whilst the rest of the fuselage was given an aluminum color to resemble alu doped surfaces:

The masked and spayed wing:

results:

And of course the parts that need detail painting and decaling as the ones shown

here, plus the other accessories that will eventually be needed like nav lights, door handles, etc.:

Everything ready for decaling, final assembly and last details:Decaling:

Triangular front window panes, main wheels and tailwheel in place:

The wing is glued:

Wing struts and nav lights in place:

.jpg)

.jpg)

.jpg)

.jpg)