(Photo from ETH-Bibliothek, Zürich, Switzerland)

(This is the step-by-step building article, for the completed mode please go to this post here in this same blog:

The mind behind this innovative use of metal (in a way different than Hugo Junkers) was Dipl. Ing. Adolph Rohrbach, later of flying boat fame.

In a way, it followed the steps of an unlikely (and unrecognized) grandfather, the Sikorsky Russky Vityaz and its successor the Illya Mourometz ( from 1913!!!!!!), very big, efficient and innovative four-engine machines used in part as commercial passenger planes.

So the Zeppelin-Staaken of 1919 was not really new or revolutionary in that regard, but it was a much modern design that took advantage of the advances in technology developed during WW1, being an all-metal, almost total cantilever monoplane. For the skeptics: it did fly, and flew well enough.

Many years would pass until such an achievement would be recognized or even copied, or re-invented, and DECADES would pass until a conceptually similar plane was designed, built and flown.

Now, the bad news: the kit:

Don't look a gift horse in the mouth.

At least not before saying thank you.

Fellow modeler Alex Bigey had the generosity and kindness to

gift this kit to me, knowing I had been looking for it for years, for which I

am truly grateful.

What can I say...careful what you wish for :-)

Now, when is a kit so bad that you just realize is worthless

or impossible?

As an example, I would say that dangerously nearing or actually tapping the "useless" frontier is where the vacuformed Dornier DO-X from Combat Models belongs. It has been lying in my garage since I bought it, time ago. And I can tell you that I have dealt with some modeling drakens, but that vac DO-X kit is so disheartening that serves now as insulation.

As an example, I would say that dangerously nearing or actually tapping the "useless" frontier is where the vacuformed Dornier DO-X from Combat Models belongs. It has been lying in my garage since I bought it, time ago. And I can tell you that I have dealt with some modeling drakens, but that vac DO-X kit is so disheartening that serves now as insulation.

The Zepp is just a notch above it. See, as soon as I opened the intact bag the Lalo Schifrin

theme started to sound in the depths of my mind...Lalo Schifrin, the Argentinean

great composer of the "Mission: Impossible" music. Sigh....

The photos show clearly how bad this kit is. The surface is

a disaster, the plastic has dirt inclusions, the edges are ill-defined, the

"panel lines" have been -unevenly- traced with a banana, some of the

wheels are oval...I mean, pal, how hard is to make a circle?

But I am not being totally fair, this kit is not just bad: it is horrid.

But I am not being totally fair, this kit is not just bad: it is horrid.

True, where else can you get a Zeppelin Staaken E4/20? Do

you think Revell is going to come to the rescue? Exactly.

So we are stuck with this Frankenkit until 3D printers can

be bought for twenty dollars and you can produce your own.

I have seen some built on the Net, with more or less

fortune, valiant endeavors that I shall not dare to criticize, or point at

their inaccuracies. These brave souls did enough, whatever the results.

Classic Plane from Germany was the perpetrator of

this...thing, many moons ago. You get your quasi-formed (the term vacu-formed

would be too optimistic) plastic of decent gauge, some clear material for the windows, a 1/72 plan that does

not coincide with some parts (i.e. fuselage length, span), a page of dubious clarity

with some notes. Hope and Faith are not included, and you have to provide your

own.

There are redeeming qualities: the plastic has a good gauge, cuts and sands easily, glues well, and its surface admits finer sanding.

Some construction notes will be jotted down as I advance, captioning the related photos.

There were some changes on the plane that can be seen in contemporary photos, most noticeably: the addition of a canopy above the cockpit. The presence in some images of a nose wheel -to prevent nose over-. Some probes that appear in some photos over the nose area. Changes in the fairings of the wheel struts/shock absorbers. The door opens sideways in most photos but in other photo is shown opening downwards (associated with the canopy). A couple photos show the legend "Staaken" painted and crossed over.The wheels are seen with visible spokes or fabric-covered. There were two sort of tripods on the wings towards the wingtips.

Some construction notes will be jotted down as I advance, captioning the related photos.

There were some changes on the plane that can be seen in contemporary photos, most noticeably: the addition of a canopy above the cockpit. The presence in some images of a nose wheel -to prevent nose over-. Some probes that appear in some photos over the nose area. Changes in the fairings of the wheel struts/shock absorbers. The door opens sideways in most photos but in other photo is shown opening downwards (associated with the canopy). A couple photos show the legend "Staaken" painted and crossed over.The wheels are seen with visible spokes or fabric-covered. There were two sort of tripods on the wings towards the wingtips.

The instructions and historical notes...well, check them against other sources:

A piece of cake? no sir, a lower right wing

Inclusions of unknown origin, dispose with precaution. Or is this perhaps a new composite? Carbon-reinforced styrene?

Oval wheels, apparently used by the Germans in the 20s:

The parts are traced around with a fine Sharpie, a pass or two with a new Xacto, bend back and forth, and voilá:

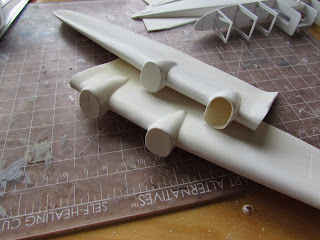

The wings follow. The other bits, do yourself a favor and replace them or scratch them. If you can replace the wheels too. The engine nacelle noses/radiators are shape-indifferent and too soft in detail. Most likely I'll be redoing them or just make them from 0:

The parts are sanded flat, carefully and constantly monitoring the results. Special attention should by given to thin those trailing edges, the bane of vac models not correctly built. The wings have some kind of built-in very subtle gull dihedral, and both upper and lower halves curve down at the triangular fillet aft of the root, so watch out:

Treatment of the surface begins, first removing the molding pips:These surfaces will need to be sanded and retraced, being the awful thing they are now:

Glue the halves of your stabs carefully, aligning the lines of the elevator horns, and not the roots, or you will end up with misaligned halves:

Glued and sanded:

The plywood blanks for the props are cut:

The center is drilled and the shape is contoured:

Sanding starts:

Almost there:

The four props. Notice that the pairs turn in opposite directions:

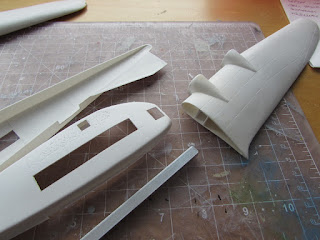

The upper and lower wing halves are glued together, aligning them at the engine gondolas and leading edges. This will leave other areas misaligned, and you will have to sand and contour them to refine the finishing:

Wings glued and their outlines sanded. Much more sanding will be involved on fixing that horrid surface:If those little blobs arranged as a line are what I think they are (i.e.: the engine top) they are not only pitiful, but also the count is wrong: five blobs instead of the six needed to represent the 6-cylinder engine top. The plan provided with the kit also shows on the top view...five cylinders. Sigh...:

A floor is patterned, cut and marked:

Ing. Dipl. Herr J. Schubert inspects the progress of the fuselage:

Herr E. (for Evil) Zoenke, the world-renown geniuz, plays tags with Helga, his zekretarin:

More formers are added:

The aft section served as bathroom, washroom, mail and baggage holders:

More internal walls, dividers and shelves:

Sink and toilet. The toilet was of Canadian design, and was know as the Bourretin:

The passenger chairs are constructed:

Cushioned armrests are added:

The chair factory. The cabin could accommodate 12 seats in three four-chair compartments, although the plane is many times referred to as being able to carry 18 passengers. Careful reading of the literature unveils the mystery: there was a provision for six more folding seats, located most likely at the nose:

Landing gear struts are made:

Control surfaces are separated to be able to pose them angled:

A preliminary test of the interior fit. Once the seats are in place the cabin roof will be glued on, and the cockpit built on it:

Several sanding sessions restored the kit surfaces to a more acceptable finish:

I decided to completely excise the awful rendition of the windows area. The idea is to insert a clear strip, mask the windows inside it, and blend the edges with the fuselage, we'll see...:

The other fuselage side receives the same treatment. The cockpit position is hollowed out. The nose (which is actually the door) is removed in order to tidy and detail it:

Keep doing dry-runs to be sure everything is going well, regarding fit and alignment:

The hatch on the fuselage top that opens into the luggage compartment (that's how it was loaded-in) is also cut:And we keep testing to be sure things are right:

The engine gondola fronts are prepared as per photos of the real plane:

Contrary to the available plans and the kit, photos show that the horn of the aileron fell short of the wing leading edge, therefore they are adjusted. Moral: check EVERYTHING YOU CAN against photos:

The nacelles are given a front plate, to aid with rigidity, alignment and future positioning of the engine:

The fuselage nose is smoothed-out:

To the right, the LG legs I made based on the plans of the Zepp on the Net and kit. To the left, the correct ones made based on photographs, with Contrail (plastic) and K&S (aluminum) airfoiled material. Consign the kit's to the dust bin:

The new fronts of the nacelles are shaped:

Meanwhile superbly mastered and cast engines kindly gifted by Matias Hagen are subjected to a process of "Maybachization", since the view of them is going to be very limited. It is something of a crime to alter Matias' casts, which are incredible:

A NOTE ON MATIAS HAGEN SUPERB ENGINES:

Matias Hagen is a master modeler of unbelievable talent that lives in Argentina. Due to the exchange policy it is at the moment very difficult to acquire imports and even to buy imported supplies locally.

What we modelers in most countries take for granted, that you can buy what you need at a reasonable price, is not the case for Matias. He makes up for that with excruciating patience, unmatched ability, painstaking dedication and nothing less than brilliant results. Matias is no doubt one of the best modelers I have ever seen, and I have seen his creation with my own eyes when I visited Argentina. What he does is something that sometimes defies understanding, because mind you: very limited access to materials and tools, no CAD or 3D printer here, extremely limited resources to spend on the hobby. How can he pull these wonders off defies reason.

Here are some of his casts, in this case a Hall-Scott and a Mercedes IV (Matias' photos of his workbench):

A link to Matias' page can be found on the right of the main page of the blog with other links.

Worth a visit. Write to him if you like what you see. I definitely do.

There is another inaccuracy that has to be dealt with in the kit. The engine was very slightly displaced from the gondola symmetry axis to one side. This shift was symmetrical, meaning all engines were "outwards" from where there should have normally been. The kit has this feature incorporated...but the displacement is to the wrong side (see attached photos showing the kit's engraved position for the cut). Whilst the kit has the engine moved towards the fuselage, the reality (and good plans) shows them moved towards the wingtip. Furthermore, the kit's shift is too pronounced, of about 1.5 millimeters, when it should be of about 0.5 millimeters:

The modified engines dry-brushed:

The exhaust pipes are made of squashed solder:

The engine had six crankcase vents. A rod is shaped:

Thin slices are cut to obtain the needed parts:

They are added to the engines (nothing of this will be visible, I don't know why I bother, but it's fun):

Photoetched bosses are added to the props:

The metal control horns are fabricated. Meanwhile, all the needed holes for rigging and locating elements are drilled in the wings:

A spar system is made. The needed dihedral will be given later on:

While I sort out many conundrums, I try to advance in somewhat less conflicting areas. Here are the decals as I understand them today:

Work starts "upstairs":

The basic block for the canopy is carved:

Although it will be further reduced in size, it already improves the looks of the fuselage and it is more in accordance with the "modern" lines of the design:

A copy is made:

You may have noticed that some photos show one or two anemometers (wind/speed indicators).

My model will not have one (not in photos on this particular configuration) but anyway here is one of the many ways of making one:

The nose/door is given some structural tubing as per photos of original:

The clear sections that will contain the windows are prepared. The actual windows will be masked, inside and out, whilst the rest of the strip is blended with the fuselage:

Photos show an instrument dial suspended to the frame of the door apparently connected to a probe on the nose via a curved hose/cable (pressure/speed/temperature indicator?), so one is fabricated:

The wing spar location is hollowed out in the fuselage sides:

The nacelles are cut out on the top as per photos to later show the engine:

Another of the many dry-runs to check things out:

Masks are applied inside (since the interior will be airbrushed) and out:

More work inside:

The wood floor decaling and detail painting begins:

The upper floor is ready:

The upholstery is applied:

Toilet (or Bourretin as it was called), sink, tap and mirror are all added:

The curtains are printed, cut and applied (double-sided):

Seats in place:

The "upper floor" in place:

No detail of the bathroom or mail shelves will be ever seen again once the fuselage is closed, but you know is there :-) :

At this point, I would like to post a contribution to the Zeppelin discussion sent by a Subject, -subjected to subjectivity, of course- from across the pond:

"Hi. I have been reliably informed that this machine was

scrapped by that little known government department which monitors style and

fashion, anything that shape needs to be discouraged.

It was actually their idea to use the camouflage skinning so

it might go unnoticed on airport dispersal areas. This only accentuated the

"interesting" appearance of this carbuncle with wings.

The natural history section of government felt the shape was

in fact prejudicial to whales and would result in increased whaling. A little

known fact is that the head of this section was related to the Pankhurst family

and she was concerned that this would lead to a further proliferation of

whalebone corsets.

Seaside

town councils discovered the deckchair plan which caused great fear that people

would choose to sit on deckchairs inside this flying whale instead and tying

knots in the corners of hankies which

were then worn as hats and rolling up ones trouser legs to expose a

gentleman's ankles. This threat would empty beaches and seriously jeopardize

the seaside retirement plans.

There are other reasons which have yet to be revealed due to

the hundred year rule and Fox (Mulder, not Fox News) expects massive reductions

to those files unless, of course, they were lost in the flood of '51. Flood actually not related to wet weather:

just MI 6 ' s tea urn leaking.

Therefore M'lud i conclude there it is therefore obvious,

considering the above that this "aircraft" never survived.

Signed

An informed but secret friend

Andrew Nickeas, Dragon-slayer (by appointment to her Majesty the Queen

)

A photoetched ladder is prepared:

It communicates the lower and upper decks via a hatch in the cockpit:

Finally the fuselage sides are joined enclosing the interior:

Little "platforms" are affixed to the nacelles to serve as a base plate for the engines:

The fuselage top and bottom seams are dealt with with successive applications of putty and sanding sessions, for me the most boring part of building...:

The engine gondolas are painted inside with a metalized black mixture:

Engines are epoxied in place:

The engine fronts are tweaked to represent the off-set cut out for the prop. Some small air intakes will be better represented with decals later on:

Dry-run:

Stab halves and tailskid in place:

A passenger stair is fashioned with styrene strips following a real one in a photo of the plane in an hangar:

It's beginning to look a lot like Xmas:

Alclad gray primer applied:

At this point the gloss black base coat is airbrushed.

Incidentally, the model at this stage looks like an unauthorized clone of the Zepp Staaken plane (this is, by the way, an uncorroborated apocryphal story) used by Evil Geniuz Zoenke, supposedly called "Ze Unfarben Gerat" or "Schwartz Helga"

It was used by Zoenke as a transport for his army of zekretarien:

The basic aluminum shade is in place, partial masking and tone variations shall follow:

Painting of some detail parts follows, and the tail surfaces that look distinctly lighter in photos are accordingly treated:

The paneling of the metal finish is accomplished using masks and different hues of paint:

Masks are removed:

Sub-assemblies readied:

The landing gear is anchored in place:

Fuel and oil tank caps in place, also the factory decal, plus a very small step aft the fuselage, used by the crew to climb on the fuselage roof. Luggage compartment doors are glued open, stair is ready too:

A view of the model with additional components:

Still a long road ahead: masking, painting and attaching the canopy; the lozenge LE decals, aileron control cables, the flying wires for the wings, details on the engine gondolas and more:

The lozenge, exhausts and other details are applied. The type and orientation of the lozenge strictly follow the best of the good resolution photographs, which determine with total clarity this was NOT AN HEXAGONAL, REGULAR NAVAL lozenge as portrayed many times, but a 5-color lozenge applied diagonally. Needless to say for those familiar with this issue, the actual colors of the lozenge pattern are open to discussion. The type and angle are not, though.

Printing the lozenge decals was not an easy task, there were several failed attempts trying to coordinate my computer screen rendition of the colors and my printer interpretation of them, plus minor changes induced by the addition of the clear varnish (I use an inkjet printer), so the final results are not that close to what my Farben Konsultant, Herr Söenke, recommended, but such is modeling life:

Aileron croissants and other details..

The completed model is here in this same blog:

http://wingsofintent.blogspot.com/2015/07/zeppelin-staaken-e420-completed.html