(Photo from the SDASM Flickr photostream)

Not sure I would call the F.32 a beauty, as this publicity suggest, but I could call it "interesting":

The plastic is thick, something you need for this specific model:

Again, you get the very basic shapes:

Here the product of a good couple hours of steady sanding:

The kits provides the two types of pants, but the early one (to the right) is inaccurate, as the real thing was more angular and flat, not rounded.

The engine gondolas are of a simplified shape, as they were in fact constituted of truncated cone sections with visible joints. May be they can be covered with an adequate styrene or foil skin.

The horizontal tail may be the only usable part of the tail, as the vertical stabilizers are too chunky and rounded. They would need scratchbuilt replacements.

Beware, though, that the horizontal tail provided is only good for the series type, as the original has the compensating "ears" typical of Fokker tails. If you are doing the prototype, you will need a new one. As I mentioned, the series planes had a straight elevator hinge line, while the prototype had compensated tips:

The fuselage completely lacks -as the rest of the kit parts- any surface detail, but corrugated sections and protruding stringers are a very visible feature of the original. Skinning and/or adding stringers may be a way to solve this shortcoming. The edges were of course much sharper, an undesirable consequence of using male molds to vacuform the parts:

The wing (L.E. on top) is of a considerable size in 1/72nd, as the original span was 99'. The shape of the tips is slightly inaccurate, and the ailerons protruded a bit in the series planes, but not on the prototype.

Once more, careful study of the intended airframe is a must:

Engines, props and right diameter wheels are scrounged from the spares:

Once the engine gondola halves are carefully sanded to a circular cross section, they are glued:

The wheels are sanded, and a cap provided:

They will be mostly hidden by the pants:

The engine gondolas are tidied:

The way the engines may go:

An idea of the size:

The vac has the correct cross-section, with the flat area in the middle at the bottom:

Spacious, no doubt. 32 passengers.

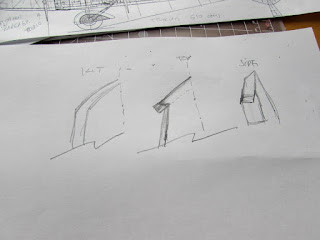

The three replacement vertical stabilizers just scratched:

Spar in the making:

I see this as an improvement:

I am thinking of scratching the horizontal tail too, as it's too thick and instead of having to add the ribs relief:

Let's play the game of the three mistakes. What is wrong with this plan?:

It has the three vertical tails associated with the balanced elevator, where it should be a straight hinge line in that case. The prototype with two vertical tails is the one that had the compensated elevator, and the lobe of the compensated area was rounder, as in early Fokker designs, thus did not have a straight leading edge all the way. So the drawing inaccurate in all accounts.

Moral: in scale modeling, don't trust your own shadow:

We better scratch a replacement horizontal tail:

Gluing the laminated spar:

And almost ready:

The wheel caps are domed with a rolling ball tool:

The resin wheels, that where discarded from a long forgotten project, were riddled with air bubbles/pinholes, so putty is liberally applied. The wheel pants are assembled:

Once in a while use a compressed air can to vent the chambers:

The interior no doubt will be laborious and time-consuming, dealing with the complex missing surface detail on the fuselage sides and gondolas will require extra care, but the real challenge I am afraid will be the engine gondola/landing gear clusters. 17 struts and connecting sections per side are needed, and fabrication, assembly and alignment will be, how to put it in technical terms...a freaking nightmare?

Not one but two restrooms, double the fun!

The wing looks good after the glue has set. There are no warps and the the trailing edges are straight:

Looking closer to what it should be now:

The areas where the fuselage and wing will interlock are excised. Still adjustment are needed to render a close fit. Ailerons are capped:

The interlocking worked fine.

Some fine tuning will be necessary, but the setting is there:

First glitch: I followed precisely the lines engraved on the fuselage sides as the wing root outline in cutting, but that was a mistake, I should have checked before cutting, as the right side airfoil chord baseline was about 2mm lower than the left. I will have to shim the right side fuselage chord baseline to pack those 2mm back:

Get familiarized with the direction of the props rotation:

Work on the cockpit area slowly begins:

And meanwhile, some reflections on the material I am studying:

After much looking, I found and era ad by the fabrics/upholstery provider -Schumacher- that described the colors for Fokker's Air Yacht!

That ladder communicated the cockpit with the cabin floor. It's just a reminder as I ordered another from a model train store with the right number of steps, lest I be chastised, ridiculed, stigmatized and excommunicated by the Modeling Inquisition, or the Modeling Brown Shirts, for defiling the Sacred Purity of the Hobby and promoting Degenerate Modeling:

A bit of work on the inst. pan., adding the engine levers console:

And before I forget, correction of the aft prop blades pitch. Blades separated from the hub:

Locations drilled and metal-pinned:

Prop on the right already corrected:

Both props corrected. Have to work once set on refining the blades a bit, as of course the variation of pitch throughout the blade has to be re-contoured too.

So I am understood: the blade should have wash-out, i.e. less pitch towards to tip, but due to the reposition now it has wash-in, i.e. more pitch on the tip than the section closer to the hub, thus some sanding is due.

It won't truly correct the shape, but it will help, thanks to the thickness of the actual part, to make the reposition virtually imperceptible:

Believe or not, primer was applied to a few small parts.

Part of the building strategy is to get out of the way ancillaries that can be completed early on, so they don't delay final assembly later.

Fine-tuning the wing-to-fuselage interlock took more time than I would have liked. Little by little, I ended up having to pack 2.5 mm* on the right hand-side of the fuselage where the wing seats to get a leveled wing, and modify the kit's engraved airfoil leading edge that I had previously carved out, which was off by a significant way. So subtracting and adding plastic, and checking all the time, the joint is ok now, although some Milliput will be necessary when the real assembly is done.

Sometimes pictures reveal especially important information for the modeler. In this case we can see that the blue areas on the side go over the belly and converge on a point mid-line, while on the nose belly they are arched as on the sides:

Little by little, more sub-assemblies are readied:

Given the nature of the vac molding, on a male master, we have to take advantage for the cutting of the cleaner angles:

More refining will be needed to get those clear panes seating right, and the forward-raking windshield at the proper angle, subtracting and adding small bits of styrene as needed:

Finally, after many aspirins, I think I got the layout of the deluxe interior, conciliating sources and checking photos.

Starting from the nose with the luggage compartment, then a lounge with four couches that served also as dinning room via the addition of snap-on individual tables, then the office, then the narrow pantries, followed by the sleeping cabin, another cabin with more conventional eight seats, then the access space with doors on both sides of the fuselage, and finally the two restrooms with toilet, sink, cabinets.

During this research stage, when more meticulous reading is done, I learned some useful things that help with actual measures on the model.

The round windows on the nose were 22ctms in diameter.

The landing gear base width was 6,10 meters.

The access doors were about 1,45 x 0,76 meters.

The nose was the luggage compartment, it was lined with corrugated aluminium below the windows, with a small radio station on passenger planes, but the radio station was in the office of the deluxe plane.

There were two narrow pantries amidship, stated as one for cold and another for warm items.

The windows were 66 x 41 ctms.

Then hallway was about 60 ctms. wide.

The angle of the windshield was 110 degrees.

The clear panels on the cockpit roof were tinted green. It seems that only the prototype had extensive glazing, all the other planes had a small number (varying) of semi-circular windows, as confirmed in photos, so some plans in that regard are inaccurate.

The ladder that communicated cabin and cockpit had four rungs, while another used to access the nose from the ground via a trapdoor had 10 rungs.

All the color information has been already given at some point in the thread.

I can now start to scratch the cabin the interior.

The windshield/cockpit side windows had a particular geometry, not quite captured in the molds, so here are some photos and a rough sketch:

There was a kind of windshield mustache or eyebrow, that went beyond the sides as clearly seen here below.

Some wheel pants had a straight base, while others had the more common angled one, that helps clear the back of the pant from the terrain when in land. The photo shows an angled one.

This below is the prototype, thus it has extensive glazing on the cockpit roof, greatly reduced in production models. The glazing arrangement is very similar, but not identical to the series planes:

Work has commenced:

Office is next:

Typewriters:

The seats for the aft cabin:

A similar windshield arrangement to the one presented before can be seen in some models of the Ford Trimotor:

A more populated cabin now:

A man can never have enough toilets...

A bit of work on the pantries:

The bulkheads are fabricated, still in their rough state. For this parts I use vac leftover backing sheets:

The wing is marked for a light panel engraving:

An easy-peasy typewriter you 3-year old can do:

The wing panel lines have been engraved, and some miscellanea is ready for a first airbrushing session:

Furniture is painted in different colors and hues, following what I can surmise from sources. Some of these had a decorative pattern, and my idea is to use the spatter nozzles from the Aztek airbrush, which I have never, ever tried before -or found a use for- to do that, combined with hand-applied details. Nothing to go crazy about, just to add sprinkles of color here and there. We will see:

That we are mercilessly lied to by companies and their advertising agencies or departments is nothing new.

Look at this Western Airlines ad, that boasts over their "First Class" Fokker F.32, and spins some lies around it.

Well, this is of course Anthony Fokker personal plane, the one I am modeling, what we would call today a luxurious executive conversion, a one-off, that had nothing to do with the series planes that the airline had, which had the normal seating seen in many cabin photos.

Oh, the tedious chore of every day making the beds of your executive plane for this super-rich lazy 1/72 types!:

The work with the Aztek spatter nozzle did not come out exactly as I hoped.

The "grain" is vary variable, and there is much dependence on dilution and pressure:

Still, a somewhat credible representation of pattern on fabric was attained. I think and old brush or toothpick can do an equal or better job. This nozzle may do well representing mud splatter and such, but not fine work:

I am now marking and drilling the holes for landing lights and control cables. I botched the location of one of the holes, had to plug it with styrene and then cut if off :

I tried my new blade from the Airwaves set which proved to be extraordinarily flimsy:Eventually the job was done, straightening the blade again and again:

Metal control horns are inserted into the ailerons:

Size compared to Ford trimotor

This is the color combination used on Tony's personal Fokker.

The vermilion was actually used just as a narrow pinstripe to separate colors and as tail outline. The gray represents the silver.

As an artist, I must confess that I have seen much more appealing schemes, but it reflects the taste of the times:

First coat of primer:

Work resumes on the behemoth, tidying up some blemishes on the surfaces:

Bulkheads are installed:

A loose dry-run of some of the elements of the interior:

Dry-run of the internal structure:

The fuselage closes perfectly around the interior, and the wing goes on without a problem (dry-run):

The last (hopefully) surface corrections are made. Compare with the size of the B.A. Eagle, in the same scale:

The supports for the bunk beds are added, as well as the bathrooms partition. Anchoring for the cockpit floor (dry run) is provided, there is a cut out that will allow the access ladder to be positioned later in the build. The area below the cockpit floor was used to store the luggage, and some photos show a cramped radio position but it's not clear on which of the Fokker this was installed:

The interior structure is primed. The two doors are cut out. The general window area is marked, as well as the nose portholes. The approach will be to cut out a larger area than the windows (as marked in the model), insert a full-length clear plastic strip, and then mask the windows and frames, a technique I successfully employed on a Ju86 airliner. I am not yet decided regarding two other paths I could take here: the fuselage sides had visible stringers that altered smoothness the fabric. The kit is unfortunately missing them. I already cut two "side" silhouettes in thin styrene sheet that I can engrave with that detail and then glue to the sides. But I am also thinking of having one of the sides with a much larger clear area (like those travel agency models) to show the complex interior detail, that would be almost entirely obscured otherwise. Since it took me more than a year to get here, I will give it some thought:

These is how it would work: