(This is the building article, for the completed model please go here:

https://wingsofintent.blogspot.com/2018/08/fiat-br20a-istres-damascus-paris-racer.html

I was aware for the first time of the Fiat BR.20A racer

modification while reading Paolo Miana's "SIAI Lost archives Vol.I: Sorci

Verdi", a wonderful book about the SM.79s that participated on the

Istres-Damascus-Paris race.

A short clip of the BR.20A.

It comes seconds after the SM79s:

https://www.youtube.com/watch?v=igq6OzzPDeE

For those interested in references concerning the three civil derivatives of the Fiat BR.20, you can consult:

-Ali d'Italia #23, Fiat Br20

-Fiat BR.20, by Pawel Babinski

-Lost Archives Chapter I, Sorci Verdi, by Paolo Miana

-Air International 1982 Vol 22 No 6 has only the briefest of the mentions, and just a blip about this versions.

-Flight Magazine during 1937, the year of the race, published small blurbs.

-Putnam Aeronautical Review 1989 01 has yet again small mentions and few images.

The profiles that appear in some of these publications have mistakes,

so once more, and as I always say: look at them, but study photos, go to

the source.

I-FIAT has its own set of modifications, and it differs noticeably from the racers, but I won't abound here on details since that isn't the variant I will be building.

The dreaded Homunculi, the modelling golems:

And it seems I caught unawares the one that should have been posed in the plane's relief facilities.

Awfully sorry for the interruption, old chap:

Sections that need excising and deleting:

This is big even in 1/72:

The provided engines, if not delicate, at least have the two cylinder rows and some detail, and are certainly better that some I have seen in much more modern releases:

As we know surface detail is not particularly subtle, but can easily be toned down:

Parts presented against plans allow for a modicum of optimism;

The transparencies that are designed to be glued from the interior have that thick wall protruding. I am not sure I will do something on the interior, but just in case, I discarded them and used styrene sheet cut to shape to fill the window openings, not present in this version:

The lower part of the fuselage is cut off, to allow shaping it to the proper contour for this version:

The turret will be occluded with a styrene disk cut to9 size and bent to match the fuselage top curvature:

A support piece is glued to hold the disk in place:

The wheels have their axles trapped between their halves, and ingenious solution for ma time were movement was desirable:

Whatever comes in halves is glued together:

Exhausts are hollowed for realism:

All parts are separated from the sprues and given a clean up, refining certain aspects of them:

The struts that brace the fins are a tad chunky, most likely they will be replaced:

The interior is prepared, but of course the racer had extensive modifications, so if I decide to build the interior and open the doors to show some of it as usual, things will change:

The fit in general is pretty good, so things are advancing smoothly, but in my kit the engine nacelles -that are part of the wing halves- were not a perfect fit, so they had to be double-clamped, to be sure that the halves were pressed against each other whilst at the same time making sure there were no side-to-side movements:

Being this an old kit, some detail solutions are not the best. Here the engine nacelle flaps are depicted in a not very subtle way, and the louvers of the original are rendered as slots.

I am not sure I would like to modify this, since it can be easily obscured with some light grime and sooth, and there are other more important areas that need attention:

The civil versions had landing gear doors, so those are fabricated. They will help to hide more efficiently the relative void of the bay:

The windows, doors and other details are covered now with putty, since they are not present in this version.

The BR.20As had an all-metal fuselage, thus those stringers have to go. This is very clear in photos, and yet many drawings of the BR.20As depict those stringers:

All that rivet galore is wet-sanded down, on all surfaces:

Since no mold is perfect the root ribs and nacelles fronts are trued. Good contact surfaces make for less puttying and sanding:

One of the two new doors that need emplacement in different locations is located in an area shared by the canopy and fuselage (the "A" version had less window panes). So the canopy has to be very carefully cut:

The doors are cut on the fuselage side too:

Alignment must be checked as you go:

The firewall and aft bulkhead are fabricated now that the access is easy:

The canopy is actually the only transparency that you will need from the kit, so you can consign the rest of the clear parts to the bin where after a few eons it could be the fuel used by a new civilization* (that is, if you do not want to use the snazzy "Italaerei posing base").

*At this rate let's hope that there would be any at all left, and that it doesn't consist of mumbling, vulgar, whiny orange mutants.:

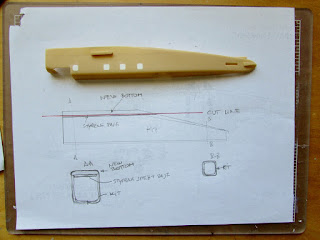

Base of the new fuselage bottom:

The props have an insinuation of the counterweights:

Those are sanded off and new ones made of punched-out disks of styrene:

The BR.20 kit transformed into a BR.20A kit:

The old doors and detail deleted, and the new ones in place:

A diagram (not to scale) of the modification:

While waiting for that photoetched set to arrive, a few panel lines are lightly engraved on the wing panels. At this point -as noted above- all rivets and raised panel lines have been sanded down, and the surface treated to a light buff, in preparation for the aluminium color that eventually will go on:

Liquid putty is applied to the seams.

Some details now. The BR.20 had two types of landing gear shock absorption: oleo-pneumatic and oleo-hydraulic.

The kit's four little toblerone-like parts that go on the legs are for the oleo-hydraulic type. But the "A" had the other type, so no chocolate boxes should be added:

The fins were missing one o the holes for the reinforcement struts, so the missing one is measured, marked and drilled:

The kit as mentioned before had some over-simplified solutions. One was to attach the control wheels to the instrument panel, which is incorrect. The wheels were paired in a common yoke, so a new part is fabricated.

The mistake of the kit maker most likely originated in known factory photos of the yoke "resting" against the inst. panel, as the elevators went all the way down, a common pose for planes on tarmac.

But if the kit were right, pilot and copilot had to have two yard-long arms, or spaghetti arms.

The horrid representation of the louvers will be occluded and re-done with printed resin ones, and the terribly overdone latches and cowl flaps will be drastically toned-down.

I just couldn't live with that sight.

Once completely shaped and made to fit, it will be used to make vacuformed halves:

The unsightly cowl flaps are sanded flat from outside and thinned down from inside with a rotary tool:

Thus "air can circulate" as it would in the original, eliminating the kit's original coarse and clumsy arrangement:

The surfaces are restored after eliminating the kit's linkages' relief:

The second layer, to be contoured, is added to the fuselage bottom:

The canopy fit was excellent. The A version had a much succinct canopy window array, so many of those frames will be sanded away (all parts dry fit):

Two vacuum-formed noses are made from the wood master:

A mist of primer is applied to the reworked area to spot blemishes:

The nose was glued one and the process of blending it in has begun:

Fuselage primed revealing spots that need more work:

Decals have arrived!:

The main elements are glued on:

The replacement thinner struts are dry-fitted, all looks good:

More primer:

Gloss white is airbrushed in preparation for the aluminum paint (yes, all the other -small- parts were airbrushed at this time too):

Aluminium color is applied to the smaller parts. The "fabric covered" ones are given a slightly different hue:

Wheel wells painted:

The base aluminium color is airbrushed:

Same panels are masked and in successive sessions are given different metal hues:

With a variety of oval masks cut in halves and quarters, the red motifs for the nose and cowls are delimited:

More tape and wrap should protect -hopefully- the rest of the plane:

All went well. Ready now for the clear coat before decaling:

Control surfaces and tail bracing on. Canopy masks off:

And this is why I am invariably suspicious of plans and drawings. They are a great help, no doubt, but almost always contain mistakes. If you don't see mistakes, you haven't looked hard enough.

Drawings depict the tail wheel as the one on the right, with no fairing, but photos show the one on the left. Both are provided by the kit:

Still, a piece of the fairing has to be removed to match photos. It always pays to do a good research:

The part is given a pin to improve anchoring:

The landing light location is drilled and a home-made lens added. A couple decals and the landing gear legs in place. The kit's landing gear is wonderfully designed and fits perfectly, how do I wish some contemporary kit makers would take a note from good ole Italeri.

The decals are provided as layered images. I used two superimposed white rectangles to obtain color density and on top the black design:

Exhausts in place:

Micro-Mark printed louvers are used to represent the ones present in photos but wrongly described on the kit (they have been filled-in, if you remember):

Application commences:

Things so far going well:

As an alternative to the Micro-Mark printed louvers, Archer also sells a sheets with different sizes of them. In this case the Mikro-Mark ones were the right size, and that's why I used those.

Application of decals and addition of small parts (like aileron mass balances) continues. The color decals have a separate white base that has to be applied first to obtain a brighter color. The long flashes on the sides are cut and applied in sections:

External photoetched parts from the Eduard set are now glued on (12 surface actuators, among them).

The set is useful and well etched. There is one nit-pick: why, oh why, put associated parts that belong to the same sub-assembly or building stage, all scattered around on diverse places that make no sense on two frets? Yes, I know space has to be optimized, but at the cost of the modelers' practicality and accessibility? me thinks not!

Eduard, group the parts together in a reasonable way, convenient to the modeler, not to you! after all, this isn't a bargain! And hey, would it produce an irreparable financial loss to add just a few darn spare parts, especially of the smaller or more fragile ones?

A note on the race numbers:

I-8 and I-10 were the race numbers of the participating Fiat BR20As.

The planes as far as I can see were almost identical. But I-8 had the race number under the left wing inverted (i.e. looking the other way). The one under the right wing is "normal", though. Intersting details you find while researching.

The home-made wheel well doors (the kit has none, since the kit's versions didn't use them) are added, as well as the wheels:

Yet more decals (including the small lettering), and the Venturi added right behind the canopy:

Awesome choice!

ReplyDeletewas this the only civil application of the BR.20?

Hi Keith

DeleteThe two Istres-Damascus racers, and I-FIAT, the record plane, were -as said in the article above- the only three civil BR.20s. Two BR.20A and one BR.20L