(This is the step-by-step building post, for the two completed models, please go here for "Liberty":

https://wingsofintent.blogspot.com/2021/03/bellanca-j-300-liberty-modified-dora.html

and here for "Cape Cod":

https://wingsofintent.blogspot.com/2021/04/cape-cod-distance-record-bellanca.html

It's delightful that more manufacturers are producing all sorts of civil types, finally helping to introduce in the market a breath of fresh air, a trend started in gran part by small manufacturers and the cottage industry long ago.

Among their offerings, Dora Wings released several boxings of the iconic Bellanca high-wing monoplane.

I have built in the past several versions of this type from the very nice vacufomed/resin kit produced by Khee-Kha Art Products:

https://wingsofintent.blogspot.com/2012/11/wright-bellanca-wb-2-paris-new-york.html

https://wingsofintent.blogspot.com/2014/09/khee-kha-art-products-172-vacuformed.html

Two Inter Island models (one of which was commissioned for the 85th Anniversary of Hawaiian Airlines to presented to their CEO, being Inter Island Airways the direct predecessor from which Hawaiian Airlines came to be, and this Bellanca the very first plane Inter Islands used.)

https://wingsofintent.blogspot.com/2014/07/172-vacuformed-khee-kha-art-products.html

https://wingsofintent.blogspot.com/2014/11/khee-kha-art-products-bellanca-ch-300.html

and:

https://wingsofintent.blogspot.com/2014/07/khee-kha-172-bellanca-skyrocket.html

Khee-Kha Art Products had released years ago also "PIA" and "Lituanica" with their corresponding sets of beautiful decals. Moreover, Khee-Kha has beautifully-cast resin floats applicable to many Bellancas (and other planes): EDO K-4650's & EDO Xa-5400's as aftermarket items.

Now, a word on the engines: The two subjects that I intend to build, Liberty and Cape Cod, had a different version of the engine than the one provided with the kit. Both (and some of the other Dora Bellancas) need J-6-9's, not J-6-9E's:

This is the Dora (incorrect for the specific plane J-6-9E version) engine front and exhaust:

And this is the resin one by Khee-Kha. To the left the parts dry-fitted, to the right the components -the engine is already partially painted-:

Back of the Khee-Kha engine with its intake tubes, already molded-in:

Adapting the Khee-Kha engine to the Dora kit will not only provide the correct version of the engine, it will also get rid of the very interesting assembly of the Dora engine, which requires 9 minute exhaust elbows to be glued between cylinders and exhaust ring, a not very fun prospect.

Going back to the Dora Wings kit, it is nice to see the type offered as a mainstream injected plastic kit. It provides comprehensive decals, photo-etched parts, vinyl masks, injected clear parts, and parts that try to cover the versions offered.

The molds look nice and clean, the level of detail is high, and the accessories are a bonus.

But, if on one hand I am happy to see products like this, on the other hand there are a number of small issues that could have been avoided by the simple expedient of doing an Internet search for the type, as abundant photos show how many details can be different between plane and plane. It is as if Dora Wings tried to squeeze too much juice from a single mold, a sort of "one-size-fits-all" approach that attempts to provide for many versions at lower cost and time, but in doing so creating some minor problems. If it's true that they provide some alternate parts to cover those versions, whilst other parts are "universal", producing again some easily-avoidable issues, as kit parts differ from the intended planes they seek to represent.

For example:

The Bellanca Liberty did not have the two Venturi on the fuselage back as described in the kit, but at the sides of the nose. The main landing gear legs are not accurate at all, and are, as molded, too skinny and the wrong shape, an inexplicable fantasy for the intended types (but correct, for example, for the Packard Bellanca and NS83, planes not represented by Dora), plus the fuselage undersides lack as well a few bumps on the belly, one of which is associated to the landing gear reinforcement struts anchoring. The stem of the wind-driven inductor compass (that has in the original a round windmill on top) was airfoiled, not round in section, but the piece is so minute it doesn't really matter, that being said, it is mounted on the middle of the back, and not to one side as described in the kit.

The fuselage side longitudinal battens, a prominent feature of the Bellanca planes, is understated, and the wing tanks on top of the wing may correspond to certain models, but not to Liberty, which had the battens not at the edges of the tank, but amidst it, plus the tanks being a tad longer in chord. There is no depiction of the massive fuselage tank, that can't really be seen anyway, but there is a back bulkhead. Liberty had two nav lights on its wingtips, above and below it, not just one at the edge of the wing, plus two nav lights on the rudder top, one on each side, not depicted in the kit. The photo-etched air scoops at the right and left side of the front fuselage are not accurate for this specific boxing (one is an intake -right side- and the other an exhaust -left side) as they are provided as flat P.E. parts, angular in section, whilst the real items were roundish in section.

Interestingly, the box art has the features right, unlike

the molded parts... miscommunication? Funny that a one-person small outfit like Khee-Kha Art Products got their Bellancas right all the way, opposite to Dora Wings that with bigger resources and mainstream technology and distribution is a bit of fumbling their way around in the fine details. And again, half an hour on the Web would have been enough, if correctly utilized, to save Dora many a mistake. Research is not a waste of time...

There is also some controversy about the colors of some of the Bellanca types released by Dora.

As you know this is common with these old types and, as I learned long ago, what is written in stone today seems to have been written in water some time later.

More or less the same detail accuracy issues are present on Warsaw, which is strange -for the two cases- as there are plenty of references online, especially photos that clearly show that many small details on the kits are inaccurate.

Thus the decision was made to change colors of Liberty, based on a different interpretation of photos, which is a personal choice of course but based on references, and to add or modify details to accurately represent the specific plane.

Here is the Liberty/Warsaw boxing:

Nicely molded:

No color call-outs, just color printed drawings, possibly not very accurate. If you look at the photo of the header, the nose is definitely a much darker hue than the rest, but other photos show a similar hue, so you make your choices. The blue may not be blue at all, and the plane it's described on a Danish site as red-white-silver, or with the wings on a light reddish brown (orange?):

Warsaw -no color call-outs either- didn't have the belly in blue, but as the rest of the fuselage, and you may notice the horizontal tail is depicted as blue on the side views and red from the top:

The Lituanica/Cape Cod boxing:

Some sprues are the same, but the other boxing has an extra sprue

The wing detail is also different for this boxing, and the span longer:

Depicting a different fuel tank configuration:

And including resin wheel pants:

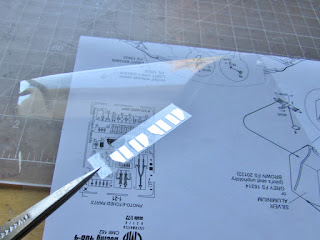

This boxing does have color call-outs, but not accurate for Cape Cod, which was supposed to be yellow and black, not orange and black, and the map color may be called into question too, as it's stated elsewhere as being powder blue. Arctic Decals produces a correction set for Cape Cod, and I just requested one:

Cape Cod also had an unusual small faring in front of the windshield -absent on the kit- in shape (but likely not in function) a bit like the one seen on some photos of Wiley Post's Lockheed Vega Winnie Mae.

All the concerns noted here are just comments I make as I go, also helped by input from other knowledgeable friends/modelers. This pursue of a fair level of accuracy may seem excessive to some, but, on the other hand, insufficient for more rigorous modelers with even higher standards. I try to strike a middle line, doing what I can -reasonably so, to my own mind- to improve the kits I work on, but I rather won't willingly go down the rabbit hole on some other aspects. No kit is perfect, and even if there are clearly bad kits and good kits, it's always up to the modeler to find his/her own bar, not forgetting to have fun in the process, otherwise what's the freaking point. So, to be clear, this is a rather nice kit, but it does have a number of inaccuracies; you may deal with them or not, the choice is yours. I am happy to build it working on its wrinkles, but I expected better fine-detail research from a new kit like this one, to be completely honest. Still, I welcome it, and any other civil effort by any manufacturer, which to me are a delight and a joy.

Most likely for technical reasons, the parts are attached to the sprues with multiple gates, a few more perhaps than in an average kit. It is wise to check the parts before removing them, as some have pips that could be mistaken for gates and accidentally removed as you clean the part.

A visible effort has been made by the manufacturer to locate the gates on the internal side of the parts, where they may be less obtrusive and easier to clean up.

I started some sub-assemblies, especially the nose, as I want to see how compatible the version-correct Khee-Kha engine may be with rest of the kit:

The instructions some glitches, here is one:

The lower half wing is a partial inset to the upper half. I had to sand the signaled areas in order to avoid a step, as the lower wing would seat a bit proud otherwise:

A little progress. Wheel halves, wing halves and elevators are glued together:The navigation lights on the wingtips are incorrect for the two versions I am building, thus have to be deleted:

The tiny pips offered by the kit as locking devices do not inspire any kind of confidence, thus metal pins are inserted in their place. The corresponding locating holes on the the fuselage sides are for some reason marked only in the interior, and have to be drilled through. Why were they not molded on the exterior is yet another modeling mystery, as if you forget to drill those through before closing the fuselage, you will be in a pickle.

The control columns have their "bends" at the wrong place, thus new ones are fabricated:

To fabricate the base sand round a rectangular section styrene strip, and drill it deep:Then sand the end to a cone shape:

Cut off the tip, sand again, and cut again:

The only photo I have of Liberty's cockpit shows only one set of brakes to the left, so only those are added instead of the four in the instructions. The kit doesn't include the actual rudder pedals, which can be seen a bit behind in photos of the plane. The firewall has some faint recesses where you are supposed to insert a tab the brakes have, but the recesses are too shallow and small, thus I angled down the brakes' tabs and glued them against that front bulkhead:

There is a problem with the front of the fuselage top, which is exceedingly thick and too tall, inaccurate for these versions (and for all the photos I have of the Bellanca, but who knows, I don't have all photos). It's easier to discern a mold line where the excess part was added on top. It has to be sanded down to that mold line and even a bit more (the part is very thick, allowing that, but be sure you still have material left whilst sanding):

If you add the top, the issue is evident:

There is a further issue with the wing. If you look at photos you see that the leading edge root section that is closer to the fuselage sort of "rounds" a bit, angling back a tad, and the airfoil seems to "get ahead" of the fuselage side and windshield. The kit does not represent this.

The fuselage top was sanded down to approximate reality. Just be sure you don't overdo it, and leave alone the very front edge, as the windshield needs to be glued against it:

Another little pearl: the instructions messed up the page number and building sequence number, so page 2 has the 1 to 6 steps sequence, while page 3 has the 10 to 12 steps, up to page 6 where steps 7 to 9 are, and so on. Talk about being all over the place. You have to cut and re-bind the central fold to obtain a proper step sequence (that now of course won't have a page number-correlated sequence). The process used by the manufacturer to achieve this is called "Quality dyscontrol".

Additional note: the tailwheel was located on Liberty (and Warsaw) almost at the kingpost, at the fuselage's end, and not ahead almost mid-stab as shown in the instructions.

There were four lenghts of tail rigging wires, going from the fin (that has a mark for it) to the stab and then under it to the fuselage, ahead of the kingpost. There is no notice Re. that in the instructions.

Cape Cod started with a tailskid, but after difficulties trying to take off, an improvised tailwheel was added to ease the takeoff run, and with that wheel made the record flight. The kit provides both.

To further compound the problem with the fuselage top being too thick and the wing position, looking at photos shows that the side windows align as in this rough sketch, whilst Dora made the side windows lower, approximately where the dotted line is:

More and more, as I study photos, I tend to incline for a light aluminium fuselage (not white as in the kit instructions), as described in some contemporary accounts, comparing the known white items in these photos (shirts, hats, caps) with the fuselage hue, which is a very light grey, somewhat in tune with the landing gear, made of metal.

https://www.criticalpast.com/video/65675035134_Otto-Hillig_Holger-Hoiriis_Liberty-plane_leave-on-a-flight-to-Denmark

http://www.criticalpast.com/store/cpdata/65675035134/big/65675035134_000986_3.jpg

http://www.criticalpast.com/store/cpdata/65675035134/big/65675035134_000870_3.jpg

http://www.criticalpast.com/store/cpdata/65675035134/big/65675035134_000348_3.jpg

And compare the white on the Danish flag cross with the fuselage:

https://digital.tcl.sc.edu/digital/collection/MVTN/id/2714/rec/3

Some of the parts of Liberty go the paint booth. Seat and isnt. pan. are painted, whilst the rest gets a coat of primer in preparation for the metal paint:

It was mentioned already that a different version of the engine is needed for Liberty and Cape Cod. But if you are building Warsaw, the kit provides the engine you see to the left of the photo with the elephant trunk, but that exhaust is actually pertinent to Lituanica, being Warsaw exhaust a bit different at the end of the pipe. The one to the right, if for whatever reason you want to use it, has those two "horns" (the elbows to connect the exhaust pipes the end) that you have to attach to the ring. The instructions state that their position is marked (it is not) rendering things a bit vague and imprecise, so look at photos for reference, they go between cylinders. Yet another thing not stated in the instructions is that the there are two very faint, almost invisible locating devices to align engine and exhaust ring, as marked in the photos bellow. They also indicate the top cylinder. It would have helped if all this was clarified:

The position of those elbows is not actually marked in the real part:

The alternate exhaust rings and associated parts:

The locating devices, not indicated in the instructions and so faint you may miss them:

As mentioned the landing gear parts do not correspond to these versions, thus most of them have to be replaced by home-made parts. To the left the kit parts, to the right to home-made ones. From top to bottom the inverted V supports that are not a rod, but an airfoiled section, in the middle the legs which are completely different, to the bottom the horizontal stabilizer's struts, in this case too wide in the kit:

Another airbrushing session:

The new resin exhaust ring needs extensions that you can simply make with styrene rod, shaping according to photos the tip (here just first pass with the sanding stick):

An alternative are aluminium tubes, first sanded in an angle:

Then bent and pinched laterally:And then given pins to attach them to the previously-drilled exhaust stubs in the resin ring:

A resemblance of the long-range fuel tank is fabricated:

It will be barely visible, if at all, but hey, how can they fly without the necessary fuel? This model once completed has to fly to the home of my friend David, from CA to IL: If you were naive enough to glue the interior to one fuselage side and then attempted to glue to other fuselage side, well, you are there for a surprise. Why is that 9 in 10 kit interiors never allow the fuselage to close properly? Having learned the hard way, I dry-fitted the components, and there is a gap:

Now to fabricate the replacements for the those fuselage vents that the kit, inaccurately for this boxing (but I think right for Lituanica) renders as flat P.E. parts, when in reality there were roundish. So a styrene rod is heated and bent (be careful) making two elbows, then separated:

The ends of the elbows are hollowed with a spherical grinding bit:

Then separated to obtain the two vents:

The fuselage is now assembled. The fuselage top fit is not bad, but seams needed filling. Other parts ready for another airbrush session to apply second color:

To replace the kit's basic shape for the inductor compass windmill and mast, very small airfoiled sections are readied, and a punched 3-disk assembly is made to mount on top of it:

Make a few, chose the best, and if all come out ok, then you have spares for future builds:Most parts needed a touch here and there to fit properly, and I am inclined to think this is the result of CAD design, as I have been experiencing this issues with many kits so designed. All may look good in a screen, but in real life many assemblies do not fit really well, as the tolerances are either too tight or plastic molding introduces some minor dimensional changes. Even the marketing model used by Dora on their website has visibly departed from what the kit assembly results on (example: the increased distance between the side windows and wing bottom: the model wings have been raised to help with the fuselage top being too high problem).

I added the nose, and, as an interface piece for the aftermarket

engine, I used the kit part that has the scallops, but sanding those

down until only leaving a ring. I glued on the home-made replacement scoops and what I think is the kit's air filter, the latter one more example of a disagreement between both components of the locating device (i.e. part as is won't fit, being the recess a tad small, same goes for the tabs used to align and secure the nose assembly, some for each component of the nose assembly):

I categorize this Dora Wings release as an "impressionist" kit: all looks wonderful in the box, and the mold quality is really good, and the details very nice, but accuracy and fit are a different matter, letting the effort down. Things, to an extent, can be worked out by a moderately experienced, but a kit of this nature should have lees issues. Maybe Dora will improve with time, and work out the wrinkles, which are many and need addressing.

The new engine needed a few passes with the sanding sting on the cylinder heads to fit inside the Townend ring. The ailerons were glued in place, and the windshield -not in the photo- was carefully dry-fitted at this stage to avoid surprises later. Like most parts in this kit, it needed to be adjusted.

As the fuselage serves different landing arrangements, the front "bent" struts do not have proper locating devices. Their location has to be guessed using two very faint marks that are meant to be drilled for the "bow legs" -none of this boxing subjects. So to glue the front wing struts in the middle of those very faint marks and aligned with the fuselage bottom would be the thing to do later:

The accurate battens are added to the wing fuel tanks, as well as the accurate fuel caps. The front wing struts are provided with metal pins (corresponding holes were drilled in the fuselage) to secure them. The accurate locations of the two Venturi -not on the fuselage top as erroneously stated in the kit's instructions) are drilled on the fuselage front (they are not symmetric, consult actual photos):

New landing gear in place (minus oleo legs), new Pitot:

A coat of primer is given to the main parts, the props, wheels and tailwheel are painted:

And again the power of research is shown. A clipping below confirming the colors as yellow and black, not orange and black as inaccurately rendered in the Dora kit, plus Dora got wrong "Cape Cod", which should be in blue, not yellow/gold as in the kit's decals:

The kit has photo-etched control horns and leads, but I wasn't happy with them, so I replaced them with aftermarket horns and later will add the leads from thin wire. The kit has the position of the horns and control leads already marked on the surface of the parts, which is good, but the aileron leads falls short of the ailerons for the bottom of the wings, where their exit points was more towards the middle of the wing chord (i.e. more of the lead was visible at the bottom than at the top, due to the wing airfoil). I usually add the horns after priming but before painting.

There are some issues with the rib count and spacing on the Dora Wings Bellancas, depending on the versions, but I will not deal with that, as it may imply new wings, which is a bridge too far, and I am happy enough correcting already all the other minor things mentioned along the build:

A base coat of gloss white is airbrushed on all parts:

Building of Cape Cod commences. As commented above, some of the sprues are different than the Liberty boxing to cater for specific parts for the versions in this boxing. Included are a nice pair of resin pants that needed exterior and wheel cavity cleanup. They lack the clue for the attachment of the front wing strut, but the fuselage features anchoring points for it and the aft strut. All anchoring points on the fuselage top are inaccurate for Cape Cod, as photos of the real thing clearly show. Once again the characteristic Bellanca batten running along the fuselage is understated:

Two details missed in all Cape Cod plans (and kits) are the different, older style Hamilton Standard logos on the prop blades, and a wire -or very thin rod- that spans between the wheel pants, just above the height of the wheel centers.

Cape Cod also had the fuselage scoops, but not like to ones in the kit or even Liberty, as they were rounded on the intake/discharge portion but more squarish where they attach to the fuselage, thus ta pair is carved:

The are glued in position on the fuselage, one intake (mouth pointing forward) on the right and one discharge (mouth pointing backward) on the left. The (longer) wing halves are glued together, and again some minor sanding here and there made for a better seating. The resin parts were cleaned up and readied, and the cabin assembly started. Preliminary test fit showed that also as with Liberty, the cabin floor and bulkhead will need sanding to allow the fuselage sides to close properly:

As with Liberty, the too thick and too high fuselage top front section has to be sanded down, as photos of the real plane show no such thing:

Be careful not to sand too much, as the plastic will become thin in the middle:

Based on the careful study and comparison of all photos I have of Liberty, and very scarce written references, here is my choice of colors for this model. As explained, I have chosen to depart from the kit's given colors as I suspect them of inaccuracy, but, it has to be said, mine also involve some degree of educated guessing, so you may study too the available material and come to your own conclusions, or follow the path of least resistance and paint it as it is (somewhat vaguely, with no real color call-outs) recommend in the kit, the choice is always yours. Some more painting (nose, battens, gear) is still to be done after the paint airbrushed here dries:

As explained the kit includes masks, which is welcome and appreciated. They are vinyl masks, not kabuki paper paper masks, therefore to me inferior in quality and performance, as these translucent vinyl masks do not offer adequate contrast, making application difficult, and many react to harsh solvents curling and lifting their edges, allowing over-spray. The kit's masks also lack precision, something noted at the windshield's "triangle" masks and especially on the side windows, where they are longer than the areas they need to mask. Nothing terrible, but could have been better:

The parts for Cape Cod (the other boxing) are separated and cleaned up. Some sub-assemblies are glued together. Once again, some of the locating devices consisting of very small cylindrical pips and cylindrical furrows on the other parts (fuselage louvered nose, bowleg landing gear) are ineffective and don't allow a seamless gap unless removed/reworked, yet another of those CAD-designed features that seem a good idea only on the computer screen. No aileron and tail control surface hinge will allow a good fit unless carefully reworked, too small tolerances again built-in during the CAD process. To the right of the photo the nice parts destined to the spares bin, always a plus for a scratch-builder like me:

The fuselage is masked to apply the red color on the nose:

Cape Cod's resin pants need to be carved inside with the help of a bur tip on a rotary tool, as apparently Dora did not bother to check, and the wheel can't be inserted as deep as it should (that is: it needs removing a bit of material from the front of the cavity, back, and depth):

Now is the turn for Cape Cod's assembly, so another fuel tank is fabricated, and the procedure to replace the kit's engine for the correct version is repeated too. As mentioned, the interior floor and back bulkhead need some material removed, as they won't fit properly inside the fuselage (not allowing the halves tho close, leaving a gap). So much for CAD, yet again:Cape Cod had a teardrop nav light on top of the rudder, it's fabricated heat-stretching some clear sprue, cutting a length, sanding the aft cone, and splicing it with the rounded end of a black rod, and then adding a mount (to be shortened later) as per photos of the original:

Extra battens as per photos are added over the wing tanks, and the fuel caps are relocated again as per photos of the plane (after the glue has set, they will be sanded down a bit to make them less conspicuous). The accurate location for the earth inductor compass mast is drilled on the fuselage top. Ailerons were glued:

Some of the Cape Cod assemblies undergo painting:

Whilst Liberty had its horizontal tail, tailwheel, and engine added:The transparencies and vertical tail on Liberty are on. The interior of Cape Cod is being readied:

Wings and struts on:

Now it's time to look at those decals.

Their quality is very good, the colors solid, excellent register; they are very thin but do not misbehave, provided you are very careful and avoid folding them.

I will be using some of the images provided in the kit, but also commissioned from Arctic Decals new wing registrations and new propeller logos (the ones provided are inaccurate). The instructions would tell you to extend the thin red fuselage stripe onto the rudder, which is inaccurate as photos prove, and add white leading edge decals to wings and struts, which is also not right according to photos. Also inaccurate are the two inverted "V" decals, as those in reality where stitches, not a black stripe, and they were located ONLY on the left-side fuselage of Liberty, not on the right. You may use the second inverted "V" on the fuselage top, close to the front, as there was another one there that the kit doesn't mention. So, as you can see, it pays to look up photos of the plane you are modeling, and not blindly trust manufacturers, they try, but not always get the "picture" right (pun intended). Image 18 should be substituted for the larger "BELLANCA". The two flags are an extremely fragile decal, as the carrier tightly follows the flag poles, so be very careful. The instructions show the "BELLANCA" superimposing partially with the color on the nose, which is incorrect, again according to photos:

Addition of the following ensues: after-market rudder and wings' nav lights, home-made landing gear oleo struts, wheels, propeller, two after-market Venturi of different sizes -one of each side of the nose in asymmetric positions-, wing strut photo-etched reinforcements, 10 control cables, 4 lengths of tail rigging, replacement horizontal tail struts, home-made inductor compass, home-made exhausts.

Still to be added: home-made Pitot and commissioned registrations:

The Arctic Decals set has arrived! Applying them now:

The completed LIBERTY model can be visited here:

https://wingsofintent.blogspot.com/2021/03/bellanca-j-300-liberty-modified-dora.html

We concentrate now on the second model, Cape Cod. The fuselage interior and prop are painted (cowls unrelated):

Fuselage sides are joined:

Then the top added. Now it's starting to take shape:

The resin pants need holes drilled for a wire that runs horizontally from one to the other, and the location of the reinforcement rod (this is missing from the kit, and was observed in photos of the plane). It is notorious that the instructions say nothing about these resin pants:

Now they can be glued, greatly adding to the exceptional charm of this particular plane:To the tailwheel structure provided in the kit, a little piece of plastic has to be added in order to match photos of the original. It is surprising how much is learned by just looking at photos. Notice that the kit part accurately ends in a small wheel, not in the usual metal shoe, that was added at the last minute to reduce drag, as the plane could not achieve flight speed in its take-off run:

New exhausts are made to substitute the kit's inaccurate ones, that will connect with the aftermarket engine exhaust ring:

A coat of primer is airbrushed on fuselage and wings to check for imperfections:

Two little bumps seen in photos but absent in the kit are added:

To provide a good base for the yellow color (and not orange as the kit says), gloss white is airbrushed:

The other side of the wings is given its white coat too. Now all main components are ready for the predominant yellow color. Black will be added after masking where it corrsponds:

The kit omitted a very visible feature of Cape Cod, a shroud that seems to enclose the compass, present in many photos. Once more: it pays to look at photos of the subject you want to kit. That part is easily fabricated:

Yellow is airbrushed:

The yellow is masked and the fuselage top is painted black, as well as the wing struts. There is a section in front of the windshield and a bit to the sides that will need aluminium painting later on:

Masks off:

Getting closer to the final assembly stage:

The kit's masks are applied to the windshield and forward windows. These are made of vinyl, too translucent, which makes difficult to see where you are positioning them, and not accurate, some being too large. A let down that could have been easily solved with paper masks, that are far better:

I am trying something. Since many photos show the side front windows slid aft, I re-used the kit´s masks and applied them on a very thin clear plastic sheet, thinner than the molded windows. Then I airbrushed the metal color. I am hoping to use these instead:

The tail feathers are glued on:

Wings are attached, the larger span of this version is evident. Metal pins were used for the wings, as the kit only provides pitiful pips that have zero mechanical strength:

All the struts, rigging and control cables in the tail area are added, plus the reinforcements of the main landing gear:This plane had three Venturi, one smaller than the other two. I am using a resin aftermarket product for those:

The engine sub-assembly is glued on, as well as those Pitots, the aft struts and the wheels inside the pants:

The corrective decal sheet from Arctic Decals behaved as usual splendidly, but you have to be very careful during application, they are thin (which is very good) and many are layered, so you have to apply two images one on top of the other, carefully. I only used four subjects from the kit's decal sheet, two small roundels that go on the fin, and the two leading edge black stripes. They did not behave well, being reluctant to leave the backing sheet, and shattering easily, being too rigid. I guess it would be a good idea for Arctic Decals to include those images too, especially because the small circles have bogus lettering, instead of the actual ones seen in photos of the plane.

(For the completed models please click on the respective links at the top of this post)

I salute you for even attempting to address the multiple color issues with Liberty/Warsaw. There are too many shade contrast shifts among the photos to be accounted for by film type alone on either scheme, & some colors were obviously changed between the 2 iterations. I'm still adamant though that dark blue wings on a transAtlantic flight makes NO sense whatsoever. Following with interest...

ReplyDeleteI completely agree with you, and may go for the orange/reddish wings tone cited above. Still, some guesswork will be involved. The risks modelers take! ;-)

DeleteAs always, Claudio, there is rtue magic happening here - wonderful skills and a beautiful model! Martin

ReplyDeleteThanks Martin!

DeleteIt's been fun.

Cheers